Introduction to kaolin

Kaolin is not only a common clay mineral in nature, but also a very important non-metallic mineral. It is also called dolomite because it is white. Pure kaolin is white, fine and soft, with good plasticity, fire resistance, suspension, adsorption and other physical properties. The world is rich in kaolin resources, with a total amount of about 20.9 billion tons, which are widely distributed. China, the United States, Britain, Brazil, India, Bulgaria, Australia, Russia and other countries have high-quality kaolin resources. China's Kaolin mineral resources rank among the top in the world, with 267 proven ore producing areas and 2.91 billion tons of proven reserves.

Application of kaolin

Natural output kaolin ores can be divided into coal kaolin, soft kaolin and sandy kaolin three categories according to the quality of content, plasticity, sandpaper. Different application areas asked for different quality requirements, such as paper coatings primarily require high brightness, low viscosity and concentration of fine particle size; ceramic industry requires good plasticity, formability and firing whiteness; Refractory demand for a high refractoriness; enamel industry requires a good suspension, etc. All this determine the kaolin specifications of product, diversity of brands. Therefore, different resources temperament, largely determine its direction of the resources available for industrial development.

Generally speaking, the domestic coal kaolin (hard kaolin), is more suitable for development as calcined kaolin, mainly used in filler aspect of different applications. Because of its high whiteness of calcined kaolin, can be used in papermaking, especially for the production of high-grade coated paper, but it is generally not used alone due to the calcined kaolin soil is mainly used to increase the whiteness, the dosage is less than washed soil in papermaking. Non-coal-bearing kaolin (soft clay and sandy clay), mainly used in paper coatings and ceramic industry.

Kaolin Grinding process

Component analysis of kaolin raw materials

|

SiO2 |

Al22O3 |

H2O |

|

46.54% |

39.5% |

13.96% |

Kaolin powder making machine model selection program

|

Specification (mesh) |

Fine powder 325mesh |

Deep processing of ultrafine powder(600 mesh-2000 mesh) |

|

Equipment selection program |

Vertical grinding mill or raymond grinding mill |

|

*Note: select the main machine according to the output and fineness requirements

Analysis on grinding mill models

1. Raymond Mill: Raymond Mill is low investment costs, high capacity, low energy consumption, equipment is stability, low noise; is a highly efficient energy-saving mill for fine powder under 600mesh.

2.Vertical mill: large-scale equipment, high capacity, to meet the large-scale production. Vertical mill is higher stability. Disadvantages: equipment is high investment costs.

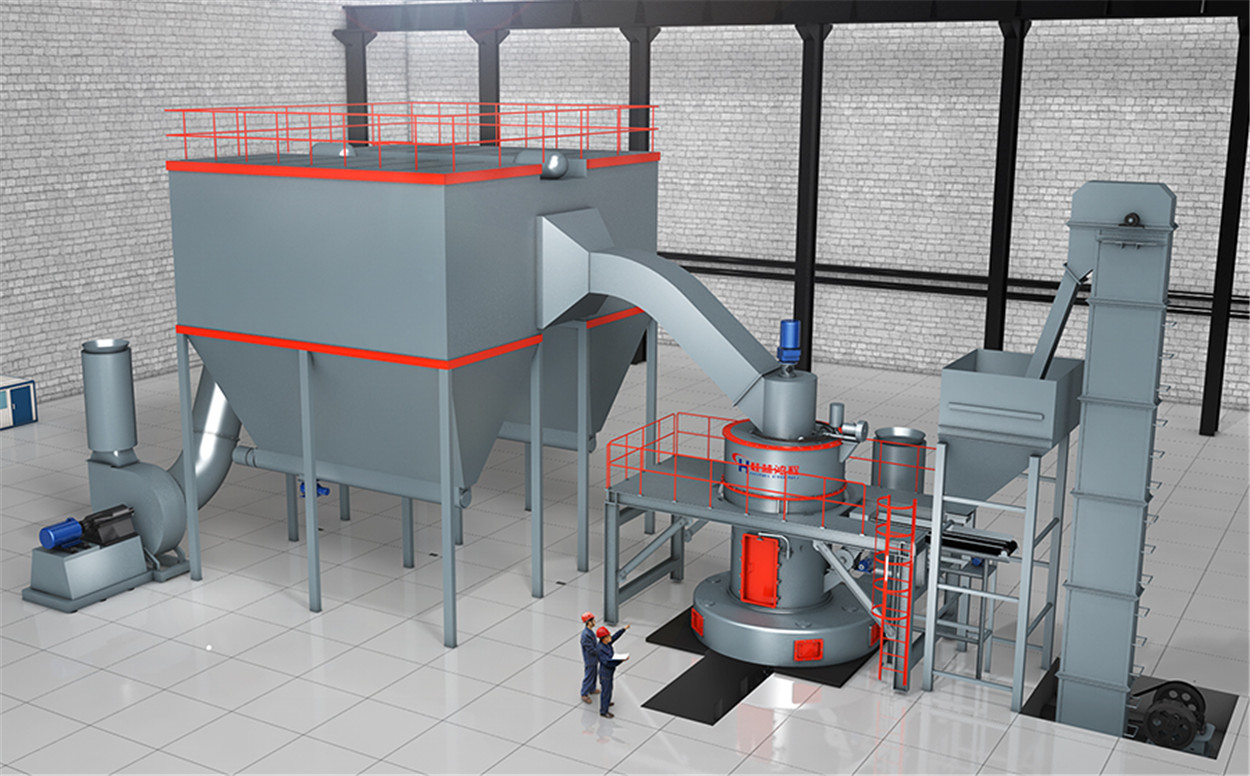

Stage I: Crushing of raw materials

The large kaolin material is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the grinding mill.

Stage II: Grinding

The crushed kaolin small materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage III: Classifying

The milled materials are graded by the grading system, and the unqualified powder is graded by the classifier and returned to the main machine for re grinding.

Stage V: Collection of finished products

The powder conforming to the fineness flows through the pipeline with the gas and enters the dust collector for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged by the powder tanker or automatic packer.

Application examples of kaolin powder processing

Processing materials: pyrophyllite, kaolin

Fineness: 200 mesh D97

Output: 6-8t / h

Equipment configuration: 1 set of HC1700

The grinding mill of HCM is a very wise choice to cooperate with such an enterprise with perfect after-sales guarantee system. Hongcheng kaolin grinding mill is a new equipment for upgrading the traditional mill. Its output is 30% - 40% higher than that of the traditional Raymond mill long ago, which greatly improves the production efficiency and output of the unit mill. The finished products produced have great market competitiveness and are very popular in our company.

Post time: Oct-22-2021